Shelvoke & Drewry Refuse Collection Vehicle types.

THE ‘T’ TYPE 1959 - 1972.

By 1959 it

had become urgent to replace the dated 'W' type which had a GRW (Gross

Vehicle Weight) of 8 tons 11 cwt when new regulations permitted

14 tons GRW of four wheels. Chief

Engineer C.K. Edwards had retired, and an abortive attempt at a

replacement ended in failure under the guidance of his successor. Tom

Tillson was recruited from rivals Dennis Bros. and design of the 'T'

type was pursued with urgency.

1959 the ‘T’ type.

The

T type introduced in 1959 has the distinctive fibreglass front which

was fitted to the wooden framed coach built cab. Only the TW and

TY cabs featured the distictive grilles above the headlights and it is

thought that with the introduction of the TY Revopak the grilles were

no longer a feature. Along with the

new ‘TY’ chassis came the Pakamatic aluminium alloy framed compression

body. The Pakamatic can be recognised by the hopper side arms that

extend along the body to produce the lifting motion to raise the hopper

clear when the body is tipped.

Photo supplied by Chris Yeadon.

1960 The TW Fore & Aft tipper.

As

a stop gap measure the TW was introduced with the ‘W’ type chassis but

the new ‘T’ type cab and a redesigned Fore & Aft tipping body, the

vast majority with Power Press compression. Distinctive features on the

cab are the grilles above the headlights and the flat roof compared to

the later 'T' series cabs.

Photo supplied by Jaap Mikkers.

1962? The TN Pakamatic.

A

narrow version of the ‘T’ series was introduced, designated TN, for use

in areas with narrow lanes or alleyways. The overall width was 6 ft 6

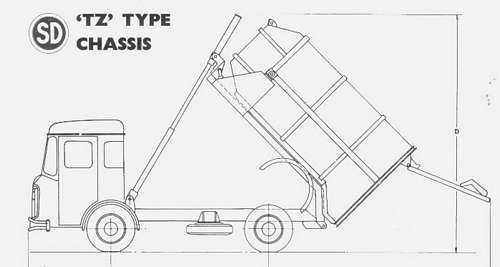

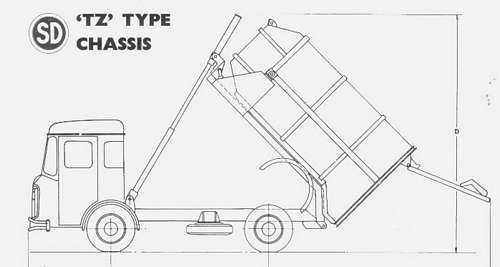

ins compared to the standard 7 ft 5 1/4 ins. The TZ chassis appeared in 1964 and around this time the TX was also introduced.

Photo supplied by Jeff Robson.

1969 The Paka Ejector.

Unlike

the Pakamatic’s tipping method the load was discharged by a pusher

plate and the hopper raised out of the way by hydraulic rams to solve

the problem of the instability created by tipping the loaded body. This

was the ejection method adopted for the later Revopak. I have

been unable to find any photos of a Paka Ejector beyond the one shown

as caption 141 in Kaleidoscope of S&D

Mid 1960’s Modifications to the Fore & Aft tipper.

The

tipping method was altered to utilise separate hydraulic rams for

forward and backward tipping of the body in place of the twin rams that

performed both operations. The hydraulic cylinders for the Power Press

were mounted inside the body instead of externally.

1971 The Revopak.

Chassis Type Definitions.

TW

8 tons 11 cwt GVW (As 'W' type) 8' 6" wheelbase 6' 10 " or 7' 5 1/4"

wide, 10' 9" and 11' 6" wheelbase 7' 5 1/4" wide, 13' 0" wheelbase 8'

0" wide.

TN 8.75 tons GVW (N=narrow) 8' 0" or 9' 5" wheelbase 6' 6" wide

TZ 12.50 tons GVW 11' 9" wheelbase 7' 0" wide

TX 13.75 tons GVW 12' 10" wheelbase 7' 6" wide

TY 15/16 tons GVW 13'- 0"/ or 15'- 0" wheelbase 8' 0" wide

Almost 11,000 T series vehicles were produced [Kaleidoscope caption 128] including 1020 TW's [Kaleidoscope caption 132] 160 TX's and 4,400 TY's [Kaleidoscope caption 130]

For other Vehicle Types click

below.